Catalytic Oxidation Technology

Catalytic oxidation is a chemical process that converts harmful pollutants into harmless compounds like carbon dioxide and water. It provides an energy-efficient, eco-friendly solution for controlling air pollution and industrial emissions.

Catalytic Oxidation – Sustainable Exhaust Air Purification

At BM Process Management, we deliver efficient and sustainable exhaust air cleaning solutions through catalytic oxidation technology, in collaboration with our technology partner Krantz. This method offers a lower-temperature alternative to conventional thermal oxidation, with strong energy efficiency and flexibility in system design.

Low-Temperature VOC Removal with High Efficiency

Using catalytic converters—based on precious metals or mixed metal oxides—VOC oxidation is achieved at reduced temperatures between 280°C and 380°C. This enables effective pollutant removal while keeping energy demand low.

Coupled with high-efficiency plate heat exchangers, up to 80% of thermal energy is recovered internally to preheat incoming air. This results in economical operation, often eliminating the need for secondary heat recovery.

CO₂-Neutral and Energy-Optimized Operation

Thanks to the lower temperature requirements, the system can be powered by electricity from renewable sources, making it a CO₂-neutral solution for industrial air purification.

Alternatively, natural gas, LPG, or in the near future, hydrogen can serve as heating sources. In optimal conditions, the system can operate autothermally, relying solely on the calorific value of the VOCs—no external energy input required.

Flexible and Modular Design

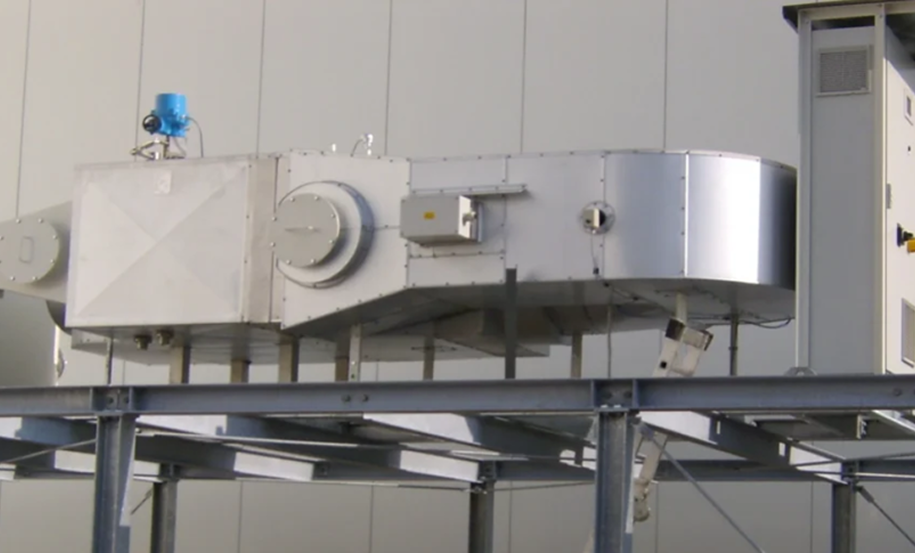

Our catalytic oxidation systems are engineered for customization and versatility. Whether installed:

- as piggyback units on dryers,

- mounted on steel frames for rooftop applications, or

- delivered as pre-assembled, pre-wired, pre-commissioned units for easy installation and commissioning