HAZOP studies – the smart way

BM Process Management has over a decade of experience in the field of HAZOP studies as a chairman, scribe and as a subject matter expert during HAZOP meetings. We strive for maximum added value and the highest possible quality in all that we do. This also goes for HAZOP and LOPA studies. Therefore, BM Process is proud to cooperate with smartHAZOP® in the field of process safety studies. This cooperation results in the highest quality and real added value for you, the customer.

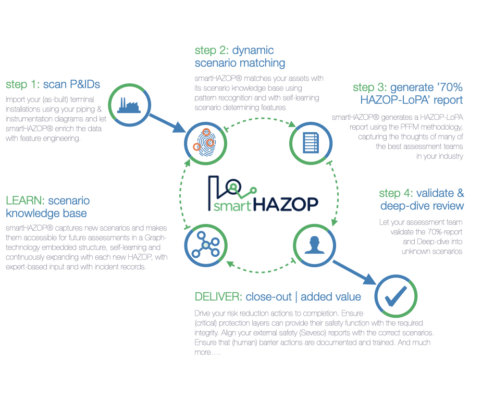

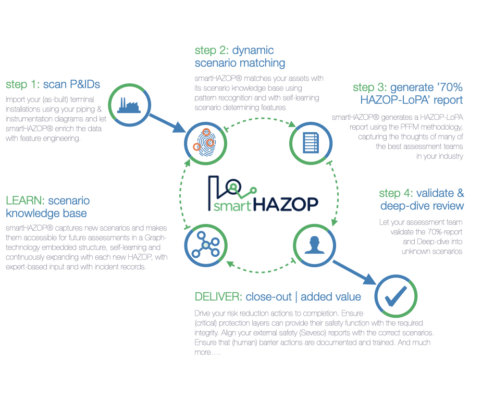

smartHAZOP® is an innovative environment that enables cross-platform support to the whole team during the risk assessment.

Industry specific scenarios

By using the smartHAZOP® platform it is possible to build on an ever-expanding knowledge base of scenarios that are specific to your industry. Scenarios that were captured, structured and enhanced by smartHAZOP® based on the input by many of the best assessment teams in your industry. Scenarios that were selected based specifically on your assets. Scenarios that include best practice safeguarding strategies. Scenarios that provide your assessment team with ALARP recommendations. And much more….

A live environment, audit proof.

smartHAZOP® is a fact-based, consistent and data driven environment that supports your teams through any Seveso major hazard control audit. No more periodic revalidation of risk assessments but a true and continuous reflection of the current risks.

smartHAZOP® makes risk assessments easy, auditable and for everyone.

Are you ready to take your safety studies to the next level and beyond? Let’s get in touch and discuss the possibilities!

When it comes to HAZOP studies the services offered are:

- Conducting HAZOP studies (chairmanship)

- Closeout of HAZOP actions and documenting the measures taken

- Review of existing designs with a HAZOP mindset

- Review of HAZOP studies

- Input during HAZOP meetings as an external expert

BM Process & smartHAZOP®. The hazop engineers.